Local Printing To Digital Printing Steps

Printing: The main brand purpose of this article is to help you understand how detailed and complex the print process truly is, and the value of working with someone who has the expertise to ensure your job is handled correctly. There is an enormous difference between a quality print job and simply sending your files to a local franchise print shop. Today, we open the doors of our Art/Production Department to give you an exclusive behind-the-scenes tour of what the print process looks like at ![]() .

.

Series 1 Exposition

Graphic Design

Graphic design is defined as the arrangement of type and visual elements along with specifications for paper, ink colors, and printing processes that, when combined, convey a visual message.[1] The graphic design stage includes concepting, page layout, typography, illustration, photography selection, color decisions, and producing final computer files.

Note: While it is tempting to hire a freelance graphic designer to create materials that can be sent directly to a low-cost printer, not all graphic designers know how to properly prepare files for printing. Once a design is approved, the files must be “packaged”. Unless the graphic designer is trained in production management, the odds increase substantially for a less than satisfactory print job. The reasons vary from missing fonts and/or images, to the use of incompatible software, for example. This generates delays, cost overruns, unanticipated proofing rounds, late-stage design changes, and sometimes disappointment over the finished job. Meticulous attention to detail at each step of the process is necessary to avoid these kinds of issues.

Creation of artwork – Important facts

Creating artwork requires taking multiple factors into account. Here are some of the most important elements to consider:

Art must be prepared in the software that is best suited for the particular task, and in a version that is compatible with the selected print shop. If the print shop uses a newer or older version than what the art file was created with, you can run into problems. Some of the industry’s standard applications include: Illustrator, a drawing program to create logos or illustration; Photoshop, a pixel-based program to manipulate photos; and In Design, a page layout program to create a single or multi-page document.

Accurate layout

Usually, files need to be built at actual size and use bleed space when appropriate. (This eliminates room for errors with the printing estimate and final printed result). If a file is not built correctly, the printer will have to spend time (and therefore charge you a fee) to readjust files to fit the correct specifications of the job.

Approved fonts

The fonts should be consistent with your brand standard and must be included with the files sent to the printer. If the printer does not have the font used in the artwork, and it has not been included with the packaged files, the printer may simply choose to substitute the fonts, producing something that is probably similar but not what you actually approved.

Suitable image resolution

Images need to be high-resolution and large enough to fit within the assigned space. The resolution should be 300 dpi (dots per inch). Anything smaller than that might result in a loss of quality.

Precise color

As with the fonts, the colors and general tone of the piece should be consistent with your brand. That said, never trust the colors of a piece being designed on a computer as the actual colors that will turn out once printed! The reason is because a computer screen and paper printing use 2 different types of processes, RGB and CMYK, to create actual colors:

- RGB (Red, Green, Blue) is an “additive coloration” mode. Think of a computer screen with a black background. In order to see the colors, some lights of red, green, and blue are “added” to the black background. RGB is typically used to render colors on monitors and computer screens.

- CMYK (Cyan, Magenta, Yellow, Black) is a “subtractive coloration” mode. It is intended to be applied to print on white or colored paper, and calculates the correct hues by “subtracting” from the initial brightness of the paper. The CMYK coloration mode is intended for use in paper printing applications and printing specific, exact colors.

CMYK is also referred to as “process colors,” which is different than spot colors (also called PMS – Pantone Matching System). CMYK uses four different color inks (Cyan, Magenta, Yellow, and Black) overlapping each other to achieve the full color spectrum. To print any multicolor image, the same four color inks are used. The press runs four imes to apply each ink individually.

Spot colors are pre-mixed inks that are applied only to the area assigned for each particular color. For example, to print a blue, brown, and red image, pre-mixed blue, brown, and red inks are used. In this case, the printing press runs only three times, which reduces printing costs. Click here to read more about spot colors.

We work on-site with the printer to ensure that the final printed product matches your brand colors as closely as possible and we advise on color corrections along the way if necessary.

File naming

Files must be named to allow printers to work more efficiently. For example, make sure there are no unusual characters in the file’s name or it may cause a printer’s computer to crash. They should be labeled with the correct extension: .ai for Illustrator, .indd for InDesign, etc. Perhaps this sounds elementary to some, but we have learned that this simple step significantly expedites the process.

File preparation to release for print

Before the artwork can be sent to the printer, here are a few steps we use to ensure the files are prepared correctly:

- Use of preflight software: Preflight software helps collect all the fonts and images, search for missing items, and avoid mistakes.

- Verification of page size settings and bleeds : Incorrect page settings cannot be fixed by simply scaling up or down, so make sure the document size is the final trim size. Bleed photos and other graphics that extend to the edge of a page must be set up to overlap the trim margins by an 1/8th inch to avoid white along the edge.

- File cleanup: Cluttered files not only confuse and frustrate printers, they compound the possibility of errors. Make sure to remove unnecessary artwork, delete unused colors, and verify that all the color names match exactly across all programs. An oversight such as not specifying whether a color is CMYK or PMS (or spot colors) might change the overall colors of a piece or even turn a four-color job into a more expensive five-color job by mistake.

The Quote Process – Communication with vendors is key

We always communicate with our vendors early in the process and negotiate the best prices for our clients without sacrificing quality. We discuss topics covering the purpose of the materials we will be printing, the final size, the quantity needed, the deadline, etc. All of this information is essential to determine the best type of press to be used (digital or offset), schedule press time, order paper, etc. Here are some of the elements we take into consideration:

- Size: dimensions of the piece (flat and final size)

- Stock: weight, finish, grade name, and color of the paper

- Inks: number and types of inks and varnishes (four-color process, PMS colors)

- Bleed: an 1/8th inch extension to the edge of a page

- Proofs: review of PDF and hard-copy versions

- File format: this information is very important to make sure the print shop can support our software/application and can open the files

- Finishing: type of trim, score, fold, assembly, and seal if applicable

- Printing and mailing or shipping date: this step is very important to determine which vendor and what kind of budget best suits the project

Prepress and the proofing process

Prepress refers to all the print production functions that take place from the moment the files are sent to the printer to the actual printing. These functions might include some of the following: receiving media files, creating proofs for review and approval, making any final changes/edits, creating the plates for the offset press, etc. At XINI, we use a 3-step final proofing process:

- Step 1: PDF proof (review copy/elements/fonts) – We request a PDF proof of the artwork from our vendors. This allows us to proofread the content one last time and make sure the piece contains no mistakes. It also lets us make sure the text hasn’t shifted or the images haven’t moved while the printer processed the files.

- Step 2: Hard-copy proof (review color match/paper) – We then receive a hard-copy printout, which lets us see the final document, check for discrepancies, and clarify how the layout is intended to look.

- Step 3: On-location press-check – Upon approval of the hard-copy proof, we go to the print shop for a final press-check in order to approve the paper, inks, varnishes, colors, etc.

Printing (offset vs. digital)

Printing is the mechanical process of applying ink to paper using an offset or digital press. The offset press is the most cost effective way of producing large volumes of printed materials, while the digital press is more commonly used for smaller volume and lower production cost. It is important to understand that the final product will look slightly different when printed digitally vs. offset, as well as from printer to printer. Proper and consistent paper selection is also a critical component of the process because color appears distinctively on different paper stocks and with or without finishes (varnish, aqueous coating, etc.). So when you need to reprint, it is best to use the same methodology, on the same paper, with the same finishes, at the same printer to match the original run as closely as possible. As part of our service, we have skilled production managers who oversee the process to ensure great and consistent outcomes.

Bindery/Finish

After a job is printed, the next stage includes one or many steps depending on the end product: cutting/trimming, folding, laminating, scoring, perforating, stitching, and binding. The last step in the bindery stage includes packaging for delivery.

Delivery

Most jobs are shipped to our clients directly or delivered to a specialized facility called a mail-house or “letter-shop” when materials are to be mailed on behalf of the client. In this stage, the addresses are computer-imprinted from the customer’s mailing list database onto the printed piece, then sorted and prepared for delivery to the post office.

As you can see, the print production process is very detailed and requires a certain level of experience and expertise. Most importantly, at ![]() , we monitor the jobs in person, from start to finish, to ensure that the highest standards are met, your brand is represented through quality materials, and that you always receive the utmost value for your investment.

, we monitor the jobs in person, from start to finish, to ensure that the highest standards are met, your brand is represented through quality materials, and that you always receive the utmost value for your investment.

Series 2 Exposition

Book production

Book production is a complex process that begins with detailed planning. Together with the printer, the paper, printing process and number of copies are specified; then, together with the graphic designer, the cover, binding and layout are developed. The prepress process concerns itself with the print data to ensure that the finished printed book should correspond exactly to your conception.

It is vital in book production for there to be a seamless interlinking of processes, know-how and commitment on the part of all XINI employees and a constant control of individual work procedures, which requires teamwork at all levels.

Book production – the way to your book begins with the book design

The manuscript is finished: now you want to see the book in print. As the author, publisher or client you may already have a concrete idea of how the book is to look. Our specialists help you realise your ideas for book design. They know which layout, cover and configuration is right for your book and will appeal to readers.

The cover is an important publicity and information medium: it is designed at XINI Prints by experienced graphic designers. The book cover represents the first visible reference to the book in any advertising effort as well as the first contact between the reader and the book, conveying far more than simply the author’s name and title. If you wish to have books printed, we will be pleased to offer you comprehensive advice on the design of the book cover as well as on the choice of the correct format, binding and paper.

Prepress and planning – your book goes to print

The individual steps in the production of a book are closely connected at LONGO. Smooth collaboration between our various departments, from pre-press to print logistics, is a major factor contributing to our high print quality, punctual delivery and costing accuracy.

Small and mini print runs are perfectly suited to digital printing, thanks to digital printing, book production is now an affordable, costable option, and not just for self publishers. If a large print run is required, the speed and precision of offset printing make it the appropriate process.

After the book has been printed it must be bound. The raw printed sheets come from the printworks and are folded, bound, cut and provided with a binding. Whether for threadless binding or thread stitching, a book for the mass-market or the coffee-table, we can also comprehensively advise you on this production step.

Books are frequently shrink-wrapped in plastic foil and bundled with booklets or magazines, and thus prepared for dispatch. We also support you in all the steps that follow the print run!

The end of the book production process results in what the XINI team always delighted to hold in their hands: a finished book! Contact us for more details. or send an email to info@xinicomms.com for our ![]() quote or simply call 07082709871, 07015883269 today.

quote or simply call 07082709871, 07015883269 today.

Going forward, We Have The Multi Step Printing Exposition

We have mentioned that printing is both a dirty business and one in which “printers” use the technical nature of the process to extract extra costs. Lithosphere’s philosophy has always been to be very open about processes and costs involved. Clearly defining the roles, input and expectations of all the parties concerned.

The following diagram and list of pre-press, printing and finishing process serves to demonstrate our commitment to smoothly fulfilling our clients expectations and our experience in managing all aspects of the print production process.

The Process in detail

Pre-press index:

|

|

|

Printing process:

|

|

|

Finishing index:

|

|

|

All of the multi step as supplied by Lithosphere may look simple but the professionalism required is more complicated than any activity in any industry but thanks to our super team put clear structure in the print/ printing communications industry in Lagos, Nigeria with super creative and innovative concept put in place.

Printing Steps

There are a wide variety of technologies that are used to print stuff. The main industrial printing processes are:

- Offset lithography

- Flexography

- Digital printing: inkjet & xerography

- Gravure

- Screen printing

Additional printing techniques were developed for very specific applications. These include flock printing, letterpress, intaglio, pad printing, and thermography.

Why a certain job is better printed using one of these processes mentioned can be read on this page about choosing a printing process.

Offset

Prepressure explained to there team that In offset lithography a printing plate, which is most often made from aluminum, contains an image of the content that needs to be printed. When the plate is inked, only this image part holds ink. That inked image is subsequently transferred (or offset) from the plate to a rubber blanket and then to the printing surface. The process can be used to print on paper, cardboard, plastic or other materials, but these have to have a flat surface.

Below is a picture of a 4 color sheetfed printing press. At the far end is the intake where individual sheets of paper are automatically fed into the press. The 4 towers or printing units each print one color, typically black get printed first, followed by cyan, magenta and yellow. The stack of printed sheets is visible on the front of the machine, underneath the press console & monitor which the press operator uses to control the press.

For higher volume work offset presses use rolls of paper. The picture below shows such a much larger web press. It is so fast that the printed paper needs to be force dried. The black unit at the end of the press is an oven.

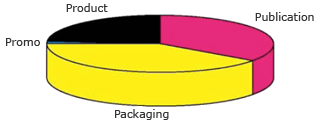

Offset is nowadays the most widely used printing technique for an extensive range of products such as books, newspapers, stationery, corrugated board, posters, etc.

There is a trend that printing promotional material is gradually migrating to digital printing while some packaging printing is moving to flexo.

There is a trend that printing promotional material is gradually migrating to digital printing while some packaging printing is moving to flexo.

You can find more information on the page dedicated to offset printing.

Flexo

In flexography the content that needs to be printed is on a relief of a printing plate, which is made from rubber. This plate is inked and that inked image is subsequently transferred to the printing surface. The process can be used to print on paper as well as plastics, metals, cellophane and other materials. Flexo is mainly used for packaging and labels and to a lesser extent also for newspapers.

Some packaging printing is moving from flexo to digital.

Some packaging printing is moving from flexo to digital.

Digital printing

Digital printing can be done in various ways. Two technologies dominate the industry:

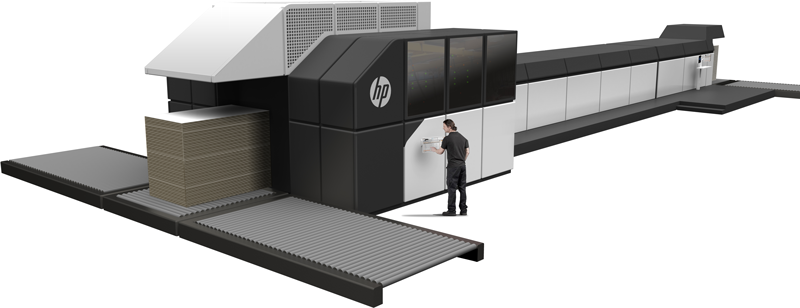

- Inkjet – In an inkjet printer the image that needs to be printed is created by small droplets of ink that are propelled from the nozzles of one or more print heads. Inkjet devices can print on a wide range of substrates such as paper, plastic, canvas or even doors and floor tiles. Inkjet printing is used a lot for posters and signage. It is also economical for short run publications such as photo books or small runs of books. In-line inkjet printers are sometimes combined with other types of presses to print variable data, such as the mailing addresses on direct mail pieces. The press shown below is the HP PageWide C500, meant for printing on corrugated board.

- Xerography – In xerographic printers, such as laser printers, the image that needs to be printed is formed by selectively applying a charge to a metal cylinder called a drum. The electrical charge is used to attract toner particles. These particles are transferred to the media that is being printed on. To make sure the toner is fixed properly, the substrate passes through a fuser that melts the toner into the medium. Laser printers are not only used in offices but also for small run printing of books, brochures and other types of document. These printers are also used for transactional printing (bills, bank documents, etc) and direct mail.

In 2009 both techniques jointly accounted for around 15% of the total volume of print.

Digital printing is increasingly utilized for print jobs that were previously printing using offset, flexo or screen printing.

Digital printing is increasingly utilized for print jobs that were previously printing using offset, flexo or screen printing.

- In short run small format (A3 size) printing, digital is taking over from offset for both color and B&W printing. Quick printers and copy shops print digitally on presses from vendors like Xerox, HP, Canon, and Konica Minolta.

- Labels are also increasingly being printed digitally.

- Billboard and point-of-sale or point-of-purchase jobs are being done by wide-format inkjet devices.

- There is a wide range of small format printers used to print on phone cases, mugs and other products.

- In book printing publishing companies start to rely more on print-on-demand. The Espresso Book Machine pictured below is well suited for that job.

There are a number of other digital printing processes that are geared towards specific niche markets:

- Dye-sublimation is a printing process in which heat is used to transfer a dye onto the substrate. Dye-sub printers are mainly used for printing on textiles, for proofing and for producing photographic prints. Some printers can print on a variety of materials such as paper, plastic, and fabric.

- In the direct thermal printing process heat is used to change the color of a special coating that has been applied to paper. This process is used in cash registers but also to add markings, such as serial numbers, to products. For this a transparent ink is used that changes color when a laser applies heat to it.

- In the thermal ink transfer printing process heat is used to melt print off a ribbon and onto the substrate. It is used in some proofing devices but seems to be gradually disappearing off the market.

Gravure

Also known as rotogravure, this is a technique in which an image is engraved into a printing cylinder. That cylinder is inked and this ink subsequently transfers to the paper. Gravure is used for high volume work such as newspapers, magazines, and packaging.

Gravure is gradually losing market share to offset for publication printing and to flexo for packaging applications.

Gravure is gradually losing market share to offset for publication printing and to flexo for packaging applications.

Screen printing

As its name implies, this printing technique relies on a screen, which is a woven piece of fabric. Certain areas of this mesh are coated with a non-permeable material. In the remaining open spaces ink can be pushed through the mesh onto a substrate. The advantage of screen printing is that the surface of the recipient does not have to be flat and that the ink can adhere to a wide range of materials, such as paper, textiles, glass, ceramics, wood, and metal.

The image below shows a screen printing press that is used to print t-shirts.

Increasingly screen printing is being replaced by digital printing.

Increasingly screen printing is being replaced by digital printing.

Additional printing processes

- Letterpress – Once a dominant printing technique, letterpress is now used for business cards, wedding invitations,…

- Flocking – used to add a (colored) velvet-like texture to paper, textiles, etc.

- Pad printing – used to print on 3-dimensional surfaces.

- Intaglio – nowadays mainly used for used stamps and paper currency.

- Thermography – This is more of a finishing process than an actual printing process. It produces raised lettering on the printed side of the paper and is used for wedding invitations, letterheads, business cards,…

Read about

Best Digital Branding Printing Arrangements To Know

Brochure – Magazine Printing

Feel Free To Always Contact Us Here At Our Head Office In Lagos, Nigeria.